The Road to Digital Simulation (3) The Importance of Data Lightweighting in Digital Simulation

As China's reform enters deep water, the country has started to make substantial adjustments to the economic structure, and the supply side and demand side are facing huge challenges. In order to face this challenge, the country has implemented the "Made in China 2025" plan, adhering to the basic policy of "innovation-driven, quality first, green development, structural optimization, talent-based", adhering to the "market-led, government-led, based on the current, long-term, overall promotion, key breakthroughs, independent development, open cooperation". The basic principles, through the "three steps" to achieve the strategic goal of manufacturing power: the first step, to 2025 into the ranks of manufacturing power; the second step, to 2035 China's manufacturing industry as a whole to reach the middle level of the world's manufacturing power camp; the third step, to the founding of the new China 100 years, the comprehensive strength of the world's manufacturing power into the forefront.

(The picture is the first pilot demonstration city of Made in China 2025 - Ningbo Port)

In the "Made in China 2025" plan, in order to cope with the increasingly fierce competition, as I mentioned in the previous article, the manufacturing industry must complete its own upgrade to survive and successfully respond to the unexpected events at any time and anywhere. Then, for the upgrading of the manufacturing industry, the factory will first improve its competitiveness from all angles, including reducing the cost of the production process, improving its own research and development capabilities and so on. In turn, it is essential to simulate the situation that may happen in the future to make a simulated assessment, which will play a good role in promoting the "Made in China 2025" plan at the national level and is also one of the ways to survive from the perspective of the enterprise itself.

According to the above-mentioned situation, a factory needs a large amount of data transmission and fast data processing capabilities in order to conduct a simulated assessment of itself and forecast the production in a certain period of time in the future. Nowadays, 5G is one of the solutions to solve the data transmission rate, so as long as the country invests heavily in the research and development of 5G, it will be the primary choice for enterprises to transmit the internal movement of the factory to the management in real time. At the same time, for data transmission, the size of the data itself is also the key to the transmission rate, and thus data lightweighting is the primary technical requirement for the increasingly large needs of factories.

So, what is data lightweighting, and what are the benefits of lightweighting:

Data lightweighting can solve the problem of difficult product data transfer process, and ensure data consistency, unify design data, improve the efficiency of communication, is the process personnel more focused on process design.

Initially, the concept of lightweighting originated in motorsports, and its advantages are not difficult to understand. Lighter weight can bring better maneuverability, and the power output of the engine can produce higher acceleration and thus gain an advantage in the race. With the computer network brought by technological progress nowadays, Hongli has brought great convenience to the whole world, data transmission has become the primary problem, and there is a demand for lighter data models and lighter algorithms. This is also true in the field of simulation, where the data of factory robots is transmitted in real time, and data such as the operation of model movements and the number of robots that can work at the same time should be fed to the management in real time, which can make the management more intuitive to manage the operation of their own factories. Then data lightness is a primary technical requirement for industrial simulation.

(Tesla manufacturing plant)

What will be the consequences if the data cannot be lightened: firstly, the data transmission rate will be affected, even if the country vigorously implements 5G to solve the data transmission rate problem at one time, the data volume itself is too huge, and the mutual transmission data between factory robots will produce time deviation, and the management will not be able to grasp the information inside the factory in real time, which will lead to the problems of the factory; secondly, it will affect the simulation Secondly, it will affect the quantity and scale of simulation. We generally think that the display of real-time data for management is on ordinary computers, so ordinary computers cannot handle such a huge amount of data calculation, which will lead to deviations in real-time data, and thus cannot discover possible problems inside the factory, affecting the quantity, quality and scale of simulation; finally, the factory and production line scanning process cannot open the overall data at the same time, which means that it affects the Finally, during the scanning process of the factory and production line, the overall data cannot be opened at the same time, which means that the real-time transmission rate is affected, and the interconnection between robots cannot be achieved, which leads to interference and factory problems.

DMworks is committed to the "China 2025" plan, and has hard requirements for simulation, and at the same time, compared with a mainstream domestic A simulation software, the comparison of the two in different functions as follows:

1.In terms of 3D C-mainstream AD data import, the mainstream A simulation software can only convert part of the C-mainstream AD data; while DMworks can convert more than 25 kinds of formats, at the same time, it is easy to modify the C-mainstream AD data tree imported from other C-mainstream AD software, and can build the data conversion environment required by the user.

2.In the parameter model, DMworks supports a variety of equipment (welding pliers, automatic grinding machine, cable, robot riser, etc.) of the parameter model library; mainstream A simulation software does not have this function.

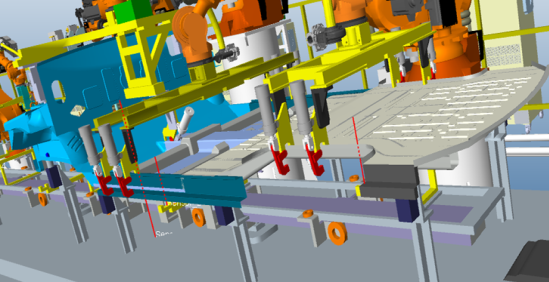

3.In the definition of mechanical kinematics, the mainstream A simulation software can define the mechanical kinematics of general equipment, but not in the equipment sensors; DMworks can define the mechanical kinematics of a variety of equipment (including 6-axis industrial robots), while providing templates for defining mechanical kinematics, so that the definition of mechanical kinematics faster, to provide sensor functions to achieve a variety of forms of simulation work (The figure shows the machine in DMworks.

(The figure shows the application of sensors for devices in DMworks)

4.In the robot simulation, the mainstream A simulation software can only use one robot "Motion Di mainstream Alog", DMworks can be multiple robots can use "Motion Di mainstream Alog"; in In terms of P-mainstream Ath & Tpos, the mainstream A simulation software has restrictions on the management of P-mainstream Ath & Tpos, while DMworks provides the tree structure of P-mainstream Ath & Tpos, group function, and can easily modify the mainstream Attribute including Motion mainstream Attribute in one window interface; the motion & behavior of the workpiece In terms of the motion & behavior of the workpiece, the mainstream A simulation software can control the workpiece attached to the robot, and DMworks can control the workpiece attached to the robot by p mainstream Attribute.

5.In terms of transportation process simulation, mainstream A simulation software can provide simple SOPs at a workstation; DMworks can connect workstations with workstations and production lines with production lines, through which simulation of factory units can be executed, providing workstations, production lines, factory units with a range of equipment movement, logic, signals and other process modules.

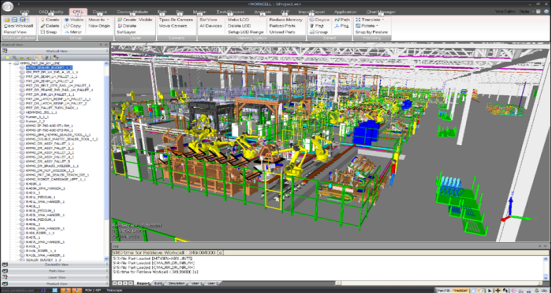

6.In terms of simulation of production line and station scale, mainstream A simulation software can execute simulation of 1~5 station scale, which cannot help to work on large-scale production line and factory scale; in terms of 3D scanning data, it does not support large-capacity 3D scanning data processing technology; in terms of cable simulation, it is relatively 1~2 robots to execute simulation. Under the same aspect, DMworks is working on production line.

(The figure shows the large-scale simulation application in DMworks that provides the scale of production line/factory)

7.In terms of human resources simulation, mainstream A simulation software can do to analyze the work environment of staff and verify the rationality of the work content of staff (RUL mainstream A); and DMworks can do more, not only to analyze the work environment of staff and verify the rationality of the work content of staff, but also to motion capture equipment linkage.

8.In robot offline programming, mainstream A simulation software can provide robot offline programming environment for simple work such as welding; while DMworks can do offline programming environment for a variety of robots such as welding, edge wrapping, laser welding, 7/8-axis robot, control feedback robot offline programming, etc. Advanced users or researchers can use the provided WSL language to build robot offline programming environment ( The offline programming environment (buttons, user interface, converters, etc.) can be built and customized according to the customer's needs (the offline programming environment required by the customer can be developed within 2~3 months).

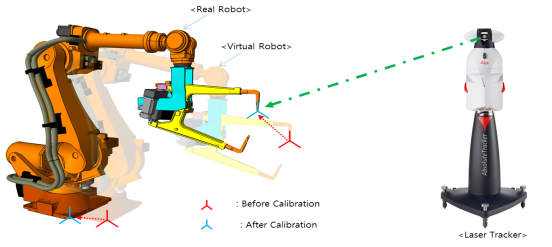

9.In terms of robot mechanical kinematics calibration, mainstream A simulation software can provide simple robot position, direction, robot station position calibration function; DMworks can input robot position, direction, robot workpiece position, direction, robot mechanical kinematics information, robot mover a variety of calibration data. In the calibration of robot motion, the mainstream A simulation software can provide the RRS module of the robot, does not support the time of welding time and other time given; DMworks can support the RRS function of modern heavy industry, F mainstream Anuc and other robots and the database of welding time and other time, can predict the correct beat, robot manufacturers provide RCS, can develop RRS environment.

(The figure shows the calibration application of DMworks in robot mechanical kinematics)

10.In the import of 3D scan, the mainstream A simulation software does not support the processing technology of handling large-capacity 3D scan data; DMworks can import large-capacity 3D scan data. In the application of 3D scan data, the mainstream A simulation software does not have this function; DMworks supports panoramic image and 3D scan data, using 3D scan data, it can provide the factory layout and factory navigation environment, and support the correct measurement of the distance between two points on the panoramic image.

11.At the same time, the mainstream A simulation software in the robot remote control, 3D PDF report are no such function; DMworks in robot remote control to the general industrial robots and special robots to provide online robot remote control and simulation technology, while customizing customer needs for special robot remote control function. At the same time in the 3D PDF, out of the 3D model, can convert or save the 3D workstation (F mainstream Actory Group) and work plan (image).

And the two in the overall comparison as follows

DMworks in the update cost of only 15%, the mainstream A simulation software is 33%; operator interface, the former simple and friendly, the latter is complex; in terms of operational difficulties, the former simple, the latter complex; in the computer hardware requirements, the former no requirements, the latter need very expensive workstations; in the simulation speed, the former fast, the latter slow; in large-scale simulation applications, 3D scanning and presentation In terms of simulation speed, the former is fast and the latter is slow; in terms of large-scale simulation applications, 3D scanning and presentation, 3D PDF, production monitoring, the former is feasible and the latter is not; in terms of controller, the former comes with and the latter needs to be purchased; in terms of offline debugging and calibration, the former is fast and accurate and the latter is not.

To sum up, DMworks is the most mature software that can realize digital simulation production, and is the creator of the real digital factory.

Meanwhile, DMworks also provides its own services to bring its software advantages into play and make its own contribution to the development of society.

Shanghai Shipbuilding Research and Design Institute, Jilin Jikei Robotics Industry Group, Lianwei Auto Parts Co., Changjiang Automobile, Guangzhou Automobile Group, Beijing Automobile, Shanghai Automobile, Brilliance Automobile and several other famous domestic manufacturing companies have improved their own characteristic industrial lines through DMworks, improved their own management, and timely found the problem knots in their own industrial lines, and then solved them. They also have their own digital factory technology training center, which is used to train a large number of engineers using DMworks and play an auxiliary role in the "Made in China 2025".

(Photo: Digital Factory Technology Training Center)

At present, all over China is still affected by the pandemic, and the road to return to work is still long. As of the editorial deadline, the country's cumulative confirmed cases are 77,041, existing confirmed 51638, cumulative cure 22,958, cumulative death 2445, existing serious illness 10,968, existing suspected 4,148, while new coronaviruses are emerging in countries around the world. Even though policies have been introduced around the world to make the road back to work easier, the work of pandemic prevention is still difficult and enterprises must not take it lightly. Finally, I wish all enterprises can successfully pass the difficult time, get rid of the pandemic and upgrade as soon as possible.

Digital Simulation Cloud Platform of Ningbo Sey Software Technology Co., Ltd (https://www.autosey.com)