Tesla Digital Factory Planning

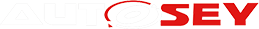

Flow Chart

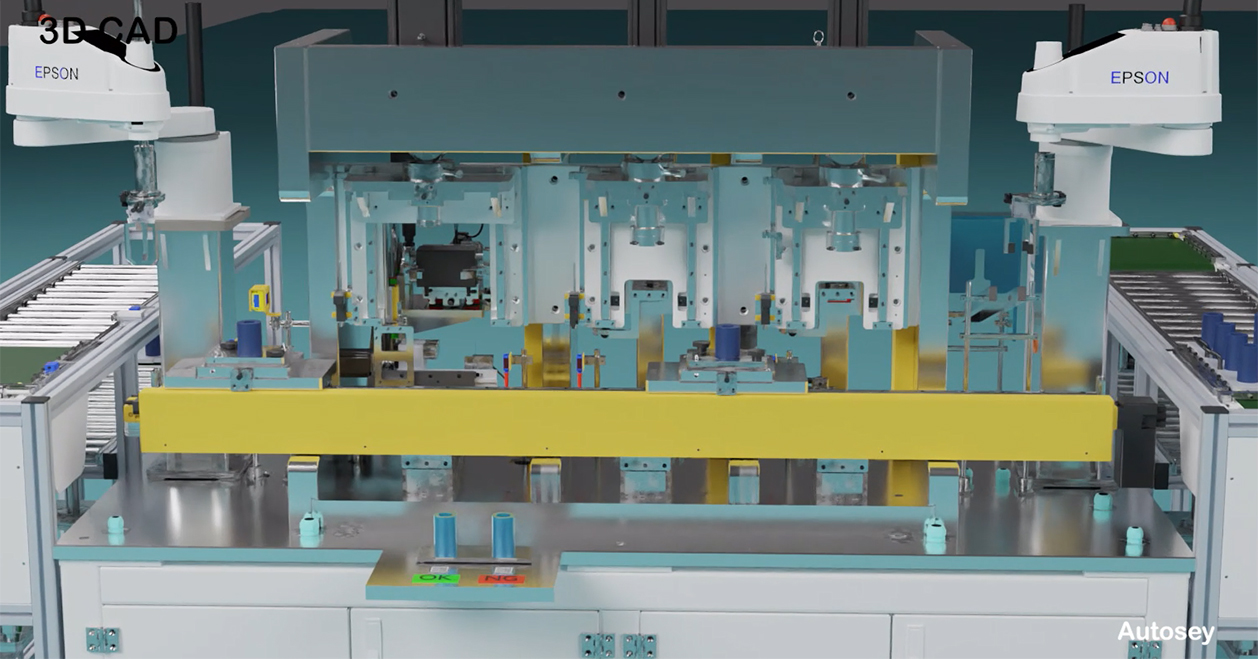

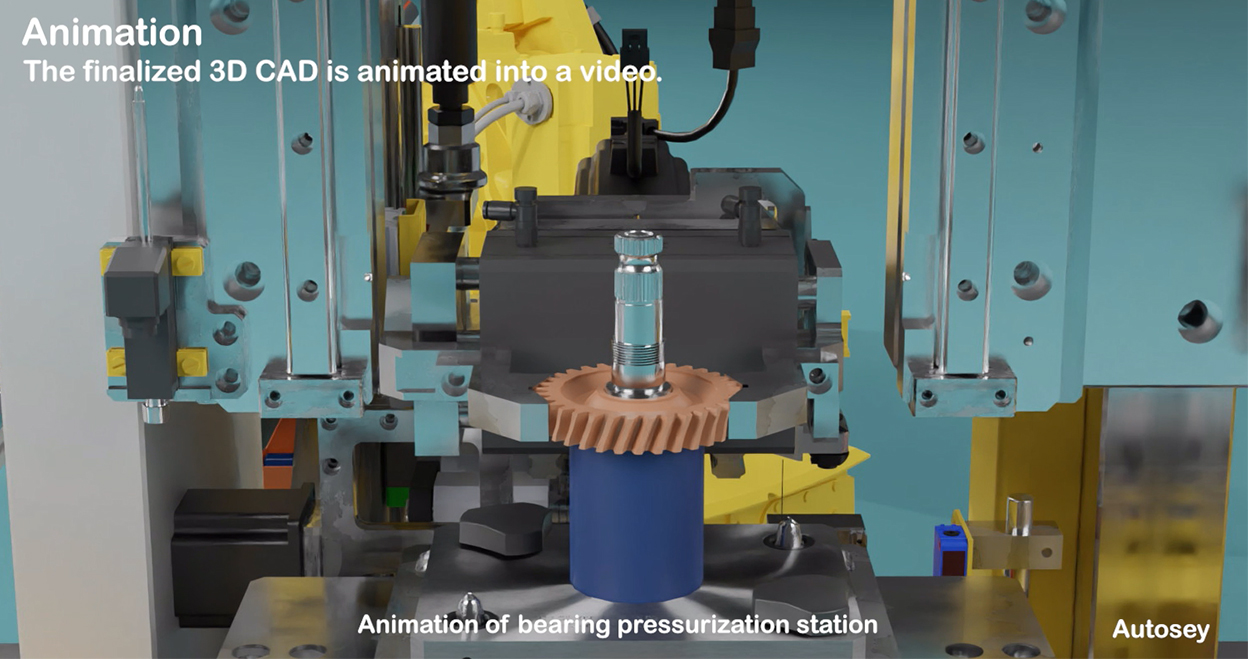

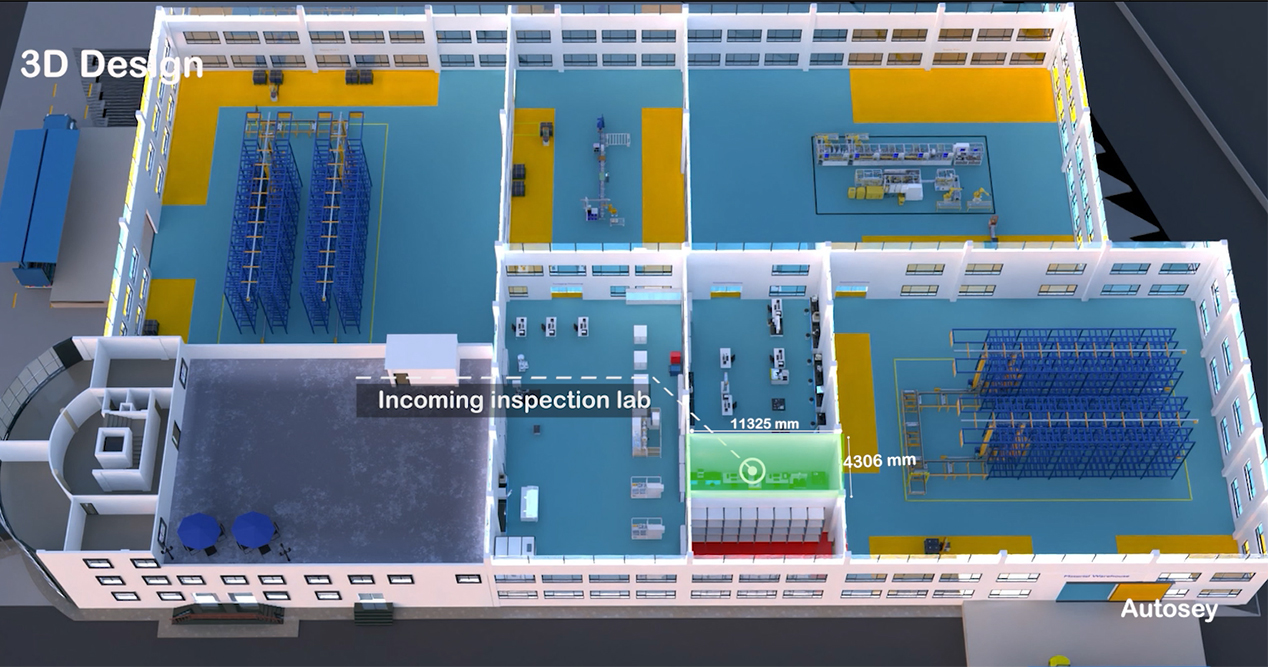

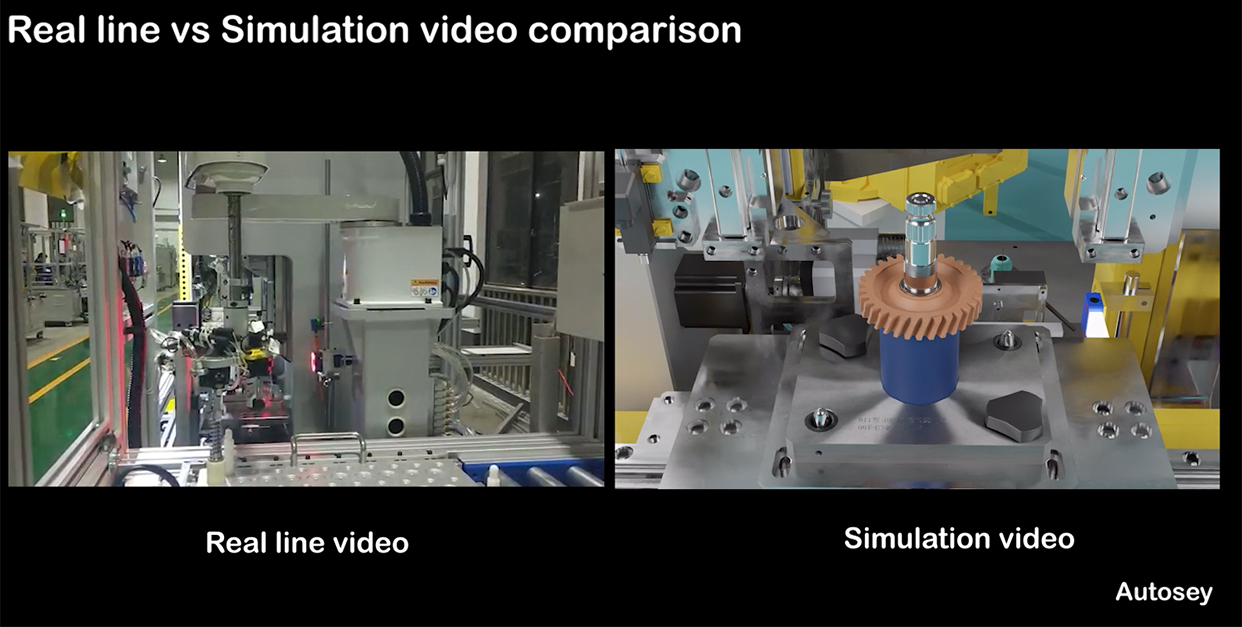

Process simulation is a valuable tool for understanding and improving complex production lines in 3D, predicting key metrics - cycle time/throughput/OEE - while exploring new ideas and optimizing the line.

Simulation helps SIE to understand and visualize complex assembly lines (from incoming to final packaging) in detail in 3D prior to procurement.

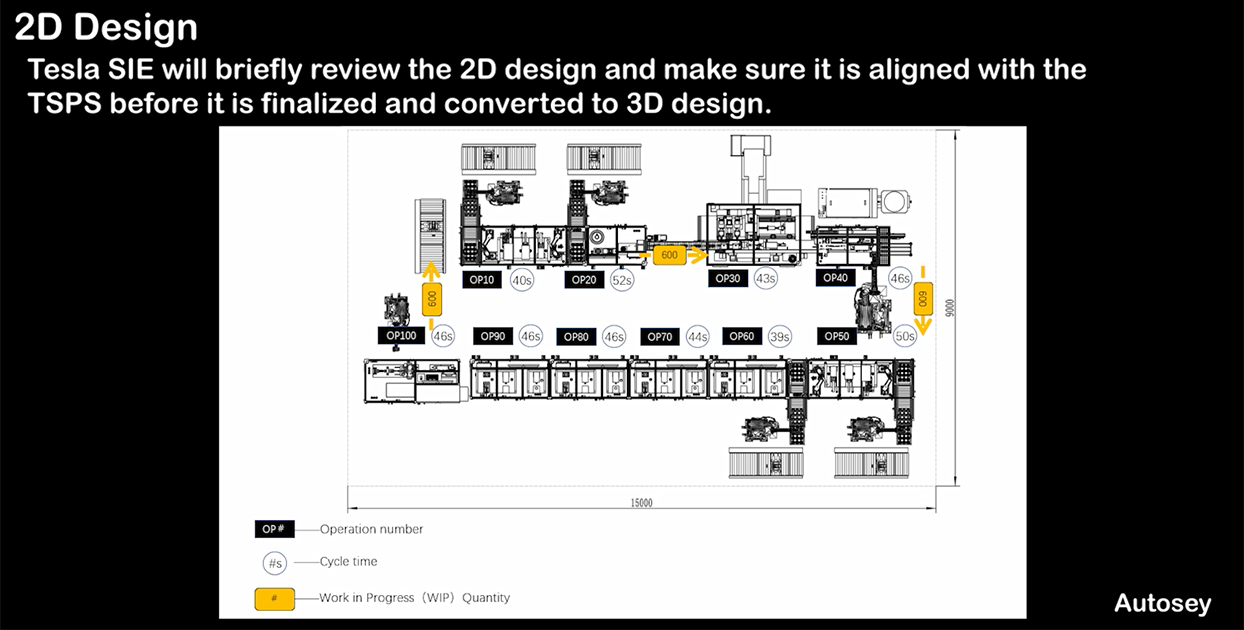

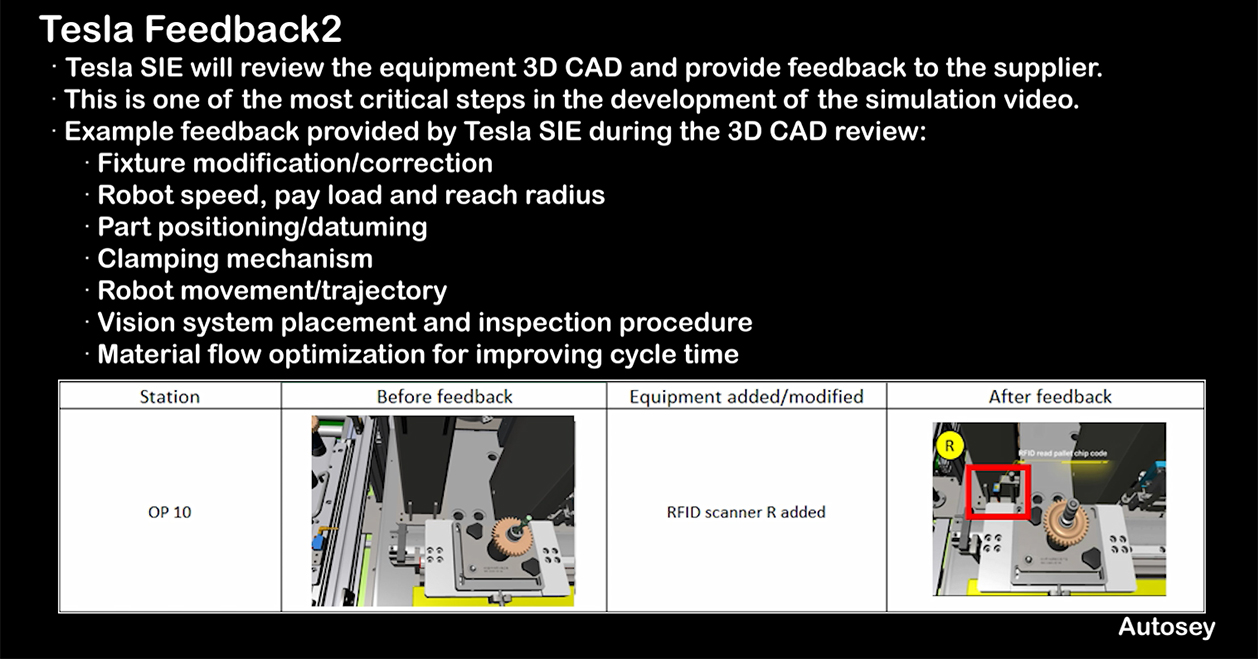

It helps SIE to identify potential failure modes (in 3D visualization) that may be overlooked during process DFM/control plan document review.

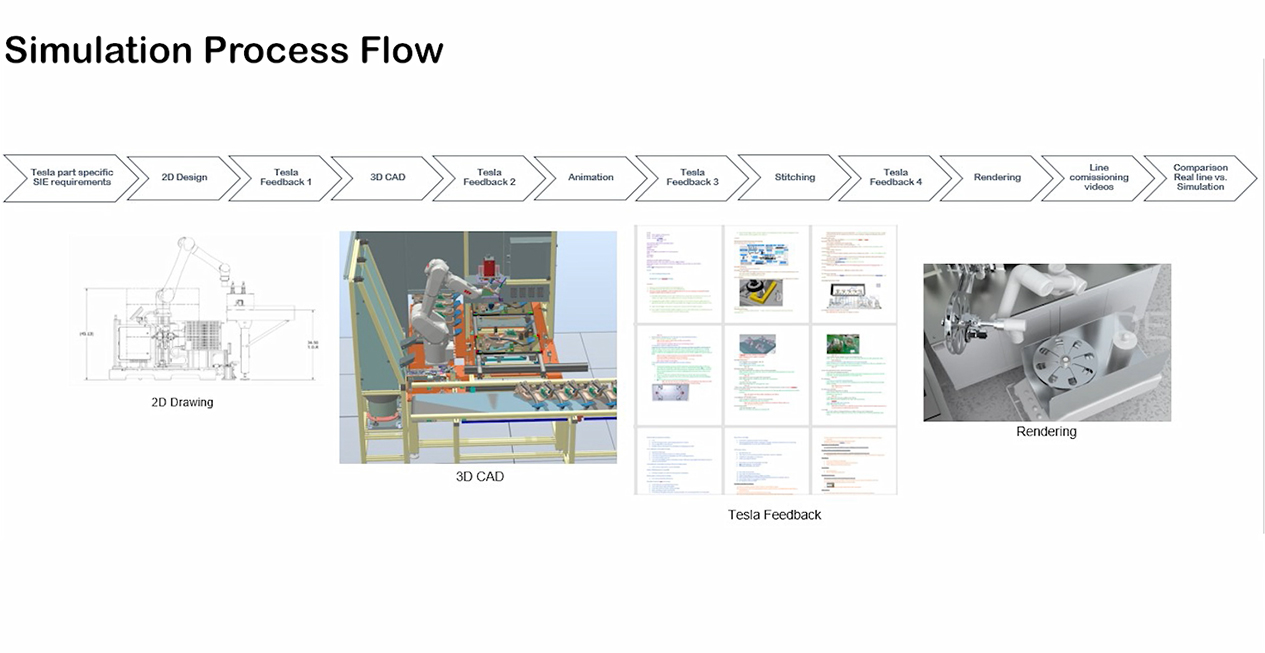

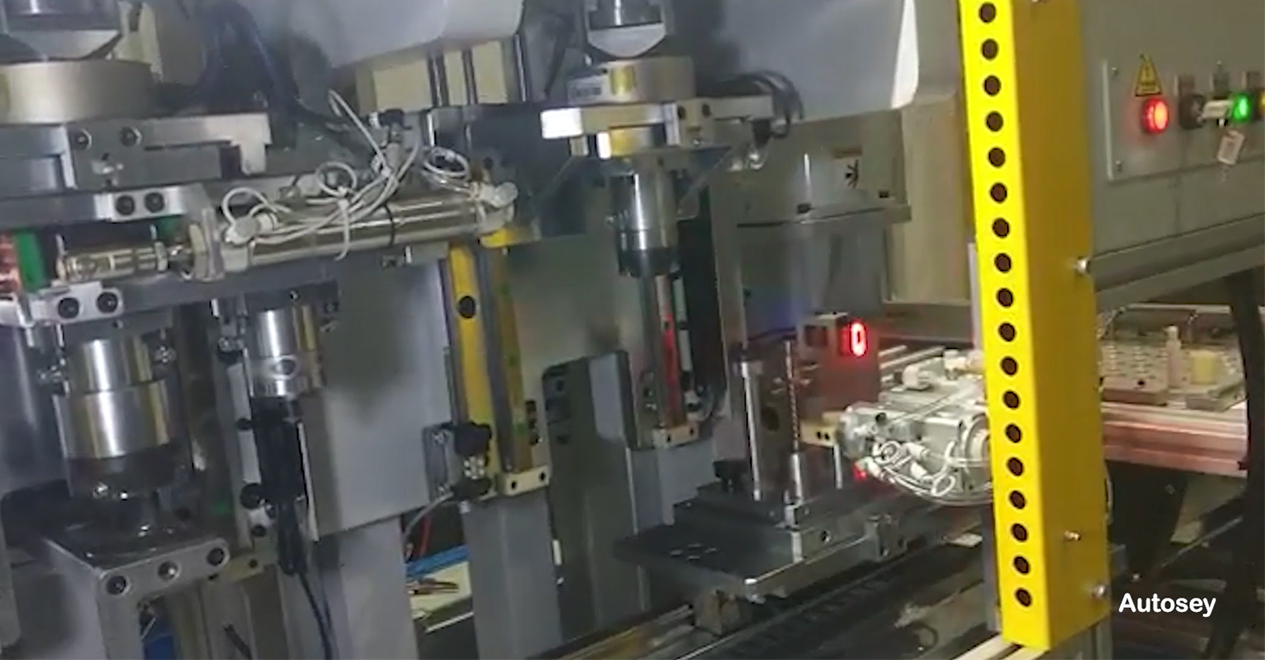

Video simulations show: line layout, material flow, NG part handling, ergonomics, process/quality control, equipment details, line balancing, periodic testing, etc.

Accelerate equipment design timelines after procurement start-up, as most of the background design work has already been completed to create process simulation videos

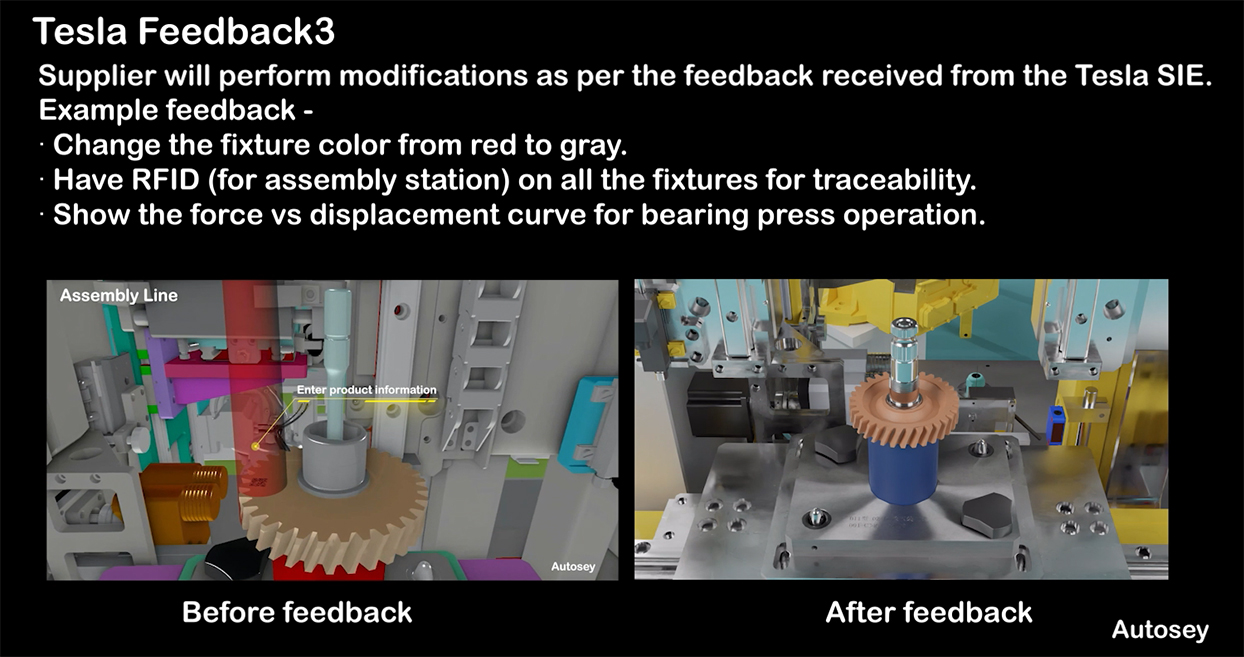

Simulations help SIE optimize and validate supplier capital expenditures, such as:

- Understanding fixture design, material flow, line layout, bottlenecks, and equipment quantities based on line balancing requirements prior to line manufacturing.

- Design of Experiments (DOE)/Agile testing of complex/advanced manufacturing processes identified during process simulation review, which significantly reduces risk and commissioning time during line commissioning.

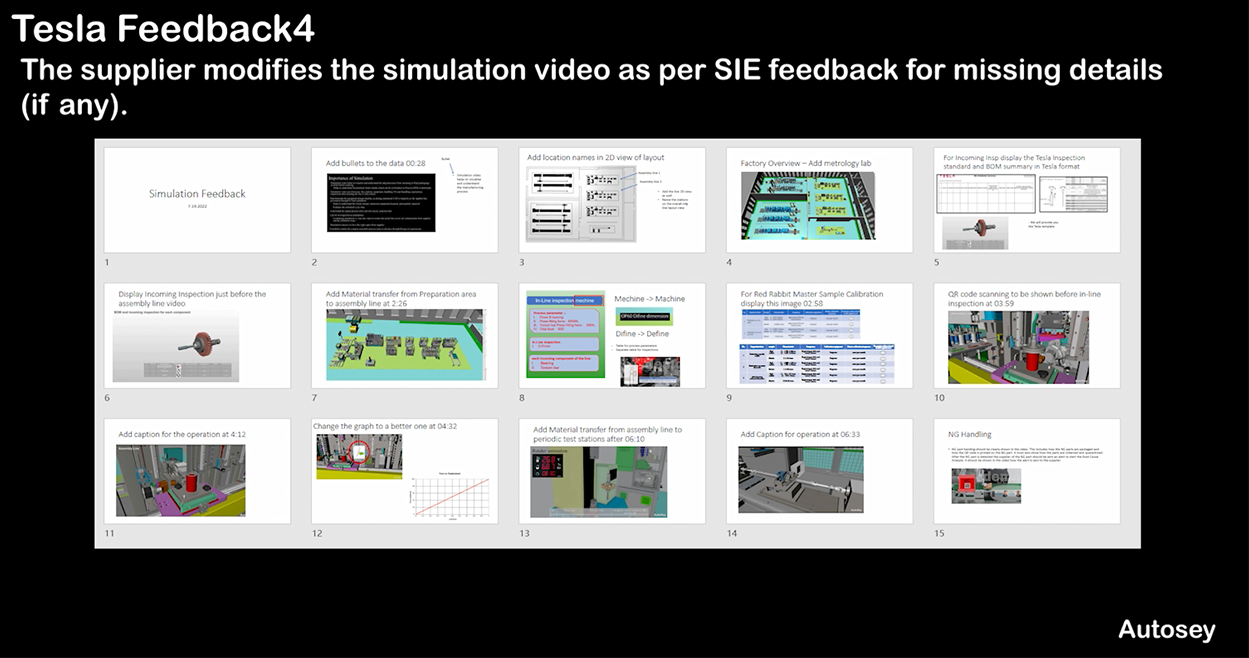

Final production video can be compared station-by-station to the final process simulation video to ensure all SIE requirements are met based on initial RFQ requirements.